Armed with a hoist rope, wire rope or chains and sheaves, cranes become very essential in lifting and dropping loads. They are important tools for modern industrial sectors who transport heavy materials from one place to another. Cranes are a work of exquisite engineering. Though, gigantic in size, they are made up of several simple machines which then carry out the tasks. Cranes have numerous variety of forms that are all designed for special use from the smallest of them to the biggest. They are not only limited to lifting loads but several other advantages too.

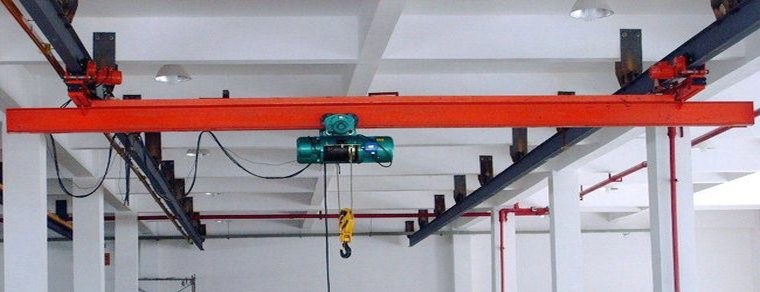

There are several types of cranes according to their different mechanical abilities and sizes, such as overhead cranes. Commonly called a bridge cane, an overhead crane consists of a parallel runway with traveling bridge spanning the gap, a hoist, which is the lifting component of the crane, travels along the bridge. That is exactly the lens being used in viewing this piece.

However, your facility or factory may require one or two types of cranes. In view of this, let’s take a look at five overhead cranes that you might need in your facility if you are a manufacturer or you work in any of the industrial sectors.

For the Jib Crane, it is usually a bit horizontal. It is mostly used to provide support for a movable part. It is most times fixed to a wall or a pillar that is mounted strongly on a floor. The Jib crane helps to move things easily, as it can rotate 360 degrees. A better improvement for the Jib Cranes is the Rotary Overhead Cranes.

These ones are basically used to carry smaller loads. The Gantry cranes are designed in such a way that it has a movable part and also a stationary part. The Gantry cranes are always built on a gantry. These gantry cranes can range from the gigantic ones, which can lift very heavy loads down to small shop cranes, which are used for smaller and simpler tasks.

The Underslung Crane is another type of crane, but this time the end carriages are placed below the gantry girders. The Single Girder Underslung Crane majorly consists of a bridge girder. The bridge girder is then connected to two end carriages. It is important to note that the two end carriages hose a pair of wheels. These wheels are powered by motor-gearbox units. The wheels are driven by motor gearbox units. Festoon cable systems are used to supply power to the wire rope hoist.

This type of overhead crane has one end of the bridge mounted on a fixed pivot and the other carried on an annular track. The bridge covers the circular area beneath. It’s used to remove lateral strains on the building walls. The Rotary Overhead Crane brings a new improvement over the Jib Cranes. The improvement makes it possible to have a longer reach and help to eliminate lateral strains on the building walls.

EOT cranes are lifting cranes commonly used across a range of different workplaces, such as assembly lines, research facilities and production plants. It consists of single or multiple beams that can move along supporting gantry rails. There are different types. There are the Single Girder ROT cranes and the Double Girder ROT cranes.

The Single Girder Bridge Crane a type of overhead crane made up of a single bridge girder, two trucks, and a trolley hoist, which runs along the tail end of the flange of the bridge girder between the end trucks. The Double Girder Bridge Crane is made up of two bridge girders, two end trucks, and a trolley hoist which travels on top of the rails that are mounted on the top of the bridge girder.

No matter the kind of crane you might need in your facility, you should purchase from a professional manufacturer, they build and design high-quality overhead cranes and other types of cranes.